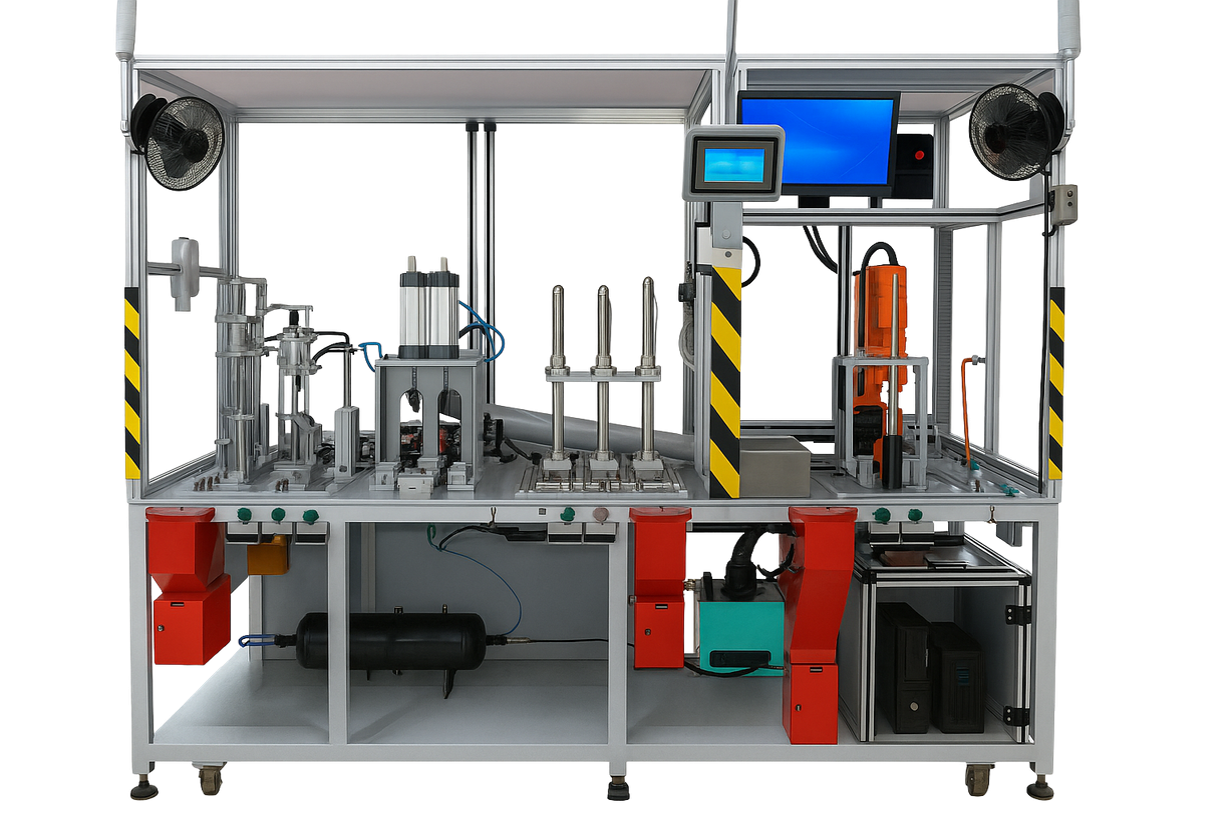

Damper Noise Test Machine

The Damper Noise Test Machine is a single-station solution for detecting unwanted noises (knocks, rattles, squeaks) in automotive dampers under simulated conditions.

Process

- Precise noise detection

- Programmable load, stroke & oscillation speed

- Data logging & traceability

PRCV (Pressure Regulating Control Valve) Assembly

The PRCV (Pressure Regulating Control Valve) Assembly & Testing Machine is a precision-engineered, single-station system designed for accurate assembly and validation of valves used in fuel, hydraulic, and emission systems.

Process

- Nutrunner assembly tools

- Leak testing

- Functional testing

- Data logging for traceability

Gear Shifter Assembly (Manual & Auto)

Fully automated Gear Shifter Assembly & Testing Line designed for precision, reliability, and traceability. Equipped with interlocks, poka-yoke systems, and real-time data traceability for foolproof assembly and quality control.

Process

- Child Part Assembly with interlock & poka-yoke

- Servo-controlled Screwing Operation

- Servo-driven Pressing Operation

- Automated Greasing Station

- Bush Pressing Station

- Real-time Traceability at each station

- End-of-Line Functional Testing

- Packing Station for finalized components

CSC (Concentric Slave Cylinder) Assembly

We offer a fully automated 6-station turnkey assembly line for Concentric Slave Cylinder (CSC) systems with integrated functional testing. It features auto feeding, greasing, changeover fixtures, camera inspection, ultrasonic welding, and laser marking—delivering high precision and flexibility at 55 seconds per unit.

Process

- Piston, Seal & Guide Tube Greasing & Assembly Washer Assembly (Plastic & Metal)

- Body, Spring & Boot Assembly

- O-Ring Assembly & Ultrasonic Welding Metal Clip Assembly

- Camera Inspection & Laser Marking

CNG Valve

The CNG Valve Assembly & Leak Testing Line is a 2-station system for precise assembly and high-pressure leak testing of CNG valves. It features servo-based indexing, poka-yoke, interlocks, and centralized data logging for high reliability and traceability. Only validated parts proceed to packing.

Process

- Component assembly with controlled screwing and positioning

- High-pressure leak testing for seal and performance validation

Number of Stations: 2 stations (manual + automated)

Number of Operators: 2 operator

Cycle Time: 60 seconds per unit

CNG Regulator

The CNG Regulator Assembly & Leak Testing Line is a 2-station system for precise assembly and high-pressure testing of CNG regulators. It features servo-based indexing, poka-yoke, interlocks, and centralized data logging to ensure error-free assembly and traceable, leak-proof performance.

Process

- Controlled assembly with servo nutrunner torque interlock

- High-pressure leak testing for performance validation

- Leak Testing for 15cc per/hr

Number of Stations: 2 (manual + automated)

Number of Operators: 2 operator

Cycle Time: 60 seconds per unit

Fuel Rail Assembly

This Fuel Rail Sub-Assembly Set Up is designed for both gasoline and CNG engine rails, featuring two stations for efficient assembly.

Process

- Injector and Clip Pressing

- Fuel rail and injector assembly

- Torqueing for Clips and Sensor

- Leak testing

Number of Stations: 2 stations (manual + automated)

Number of Operators: 2 operator

Cycle Time: 60 seconds per unit

News from Infinity Automation

Trade fairs & Events

Contact us

Headoffice

Would you like to contact Infinity Automation online?

Then use our online contact form!

.png)