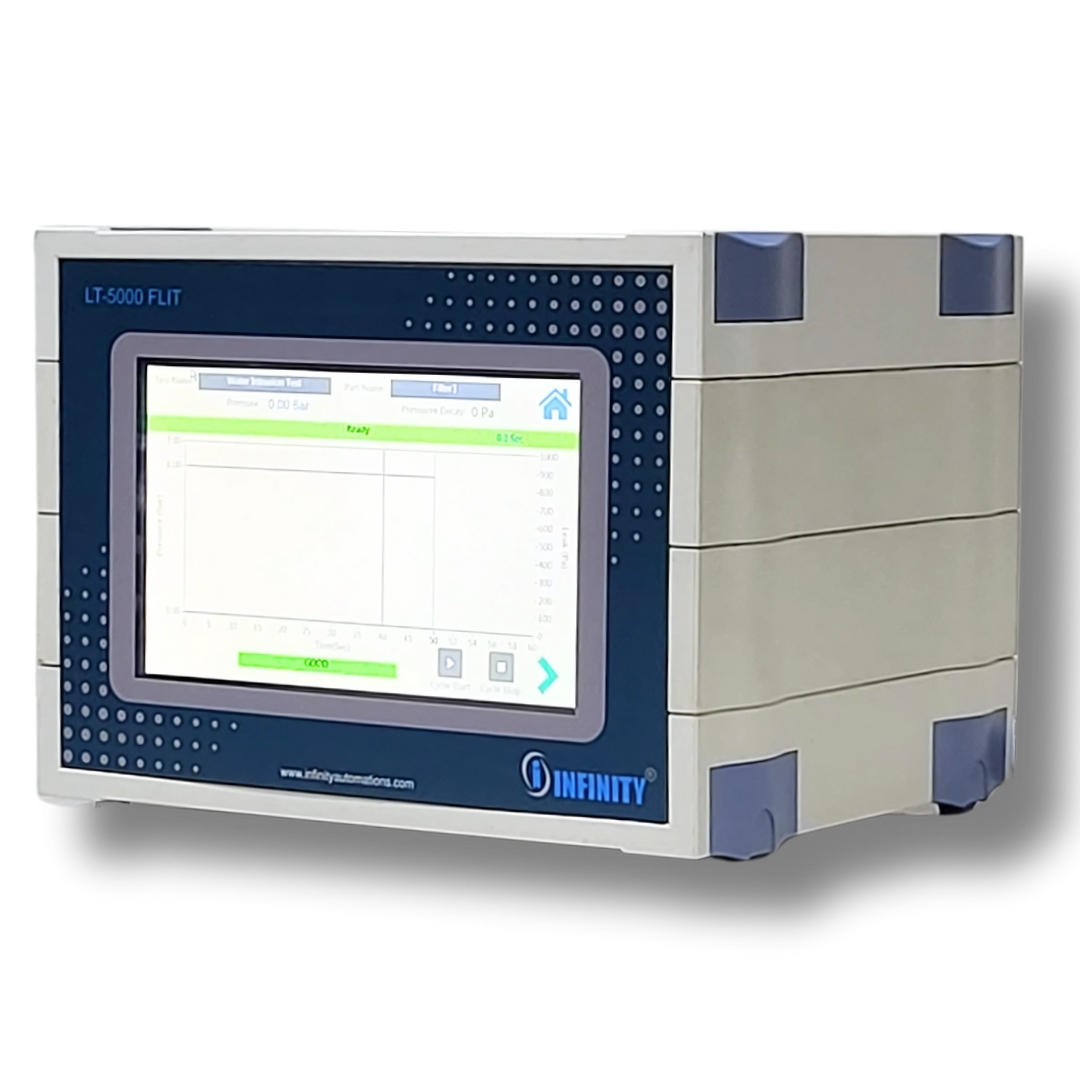

Filter Integrity Tester: LT-5000 FLIT

“Integrity Assured, Intelligence Built In..!”

The LT-5000 FLIT Filter Integrity Tester is a compact, high-precision system designed for reliable filter integrity measurement with advanced security and automation features.

CComply with ASTM, FDA 21 CFR Part 11, USP 1207, NABL, CE, ISO 9001:2008, EMA ANNEX 11, ProdNx

Features

- Offers a wide range of integrity testing, compatible with all existing test methods.

- Integrated security framework offering password protection, permission control, hierarchical authority grading, and electronic signature support.

- Compatible with SAP, ERP communication with various protocols like Profinet, UDB, OPC etc.

- Dedicated development team for customization

Application

- Filter Integrity Testers play a vital role precisely in the food and pharmaceutical industries

- Product range includes:

- Capsule filter housings

- Industrial filter cartridges

- Membrane filtration systems

- Syringe filter

Technical Specifications:

| SPECIFICATIONS | MICRO LEAK DETECTION |

|---|---|

| Input power | 100 to 260 VAC, 50 Hz, 120W |

| Environmental Condition | Ambient Temperature: +5°C to +40°C Relative Humidity: 10 to 80% |

| Unit | m bar/kpa/pa |

| Test Scope | BP: 50 to 9000 mbar DF: up to 1000 ml/min WI: 0.01 to 150ml/min |

| Test Accuracy | 0.075% |

| Modes | Bubble Point Test, Diffusion Flow Test, Water Intrusion Test |

| Print Function | Compatible |

| Internal Memory | Stores upto 5 years of data |

| Test Report | In-built non-editable, printable PDF format |

| Display Screen | 7"/10" color touch screen - resistive/capacitive |

| Connectivity | Serial Ethernet & USB |

| Weight | 6.5 Kg |

- Tamperproof and Non-Editable Audit Trail Data Format

- The time stamp of the change of the parameter value and the user making the change

- The audit trail records the following details:

- User Creation

- User Login/ Logout

- Wrong attempts at login

- User Block / Unblock by Administrator

- Old value and new value of the parameter change

- The time stamp of each event

- Electronic signatures used to sign electronic records must be unique to the individual, verifiable, and protected from unauthorized use.

- There must be controls in place to ensure that electronic signatures are applied only by authorized signatories and that they cannot be tampered with

- Review of the reports on the HMI Screen for Production, Alarms, and Audit Trail.

- Storage limit can be interlocked in terms of the number of batches produced or % of the memory consumed.

- HMI offers basic connectivity for data exchange with Central SCADA / MES / ERP by following the means:

- Through OPC UA

- Through Data file transfer

- Through USB / SD Card Backup

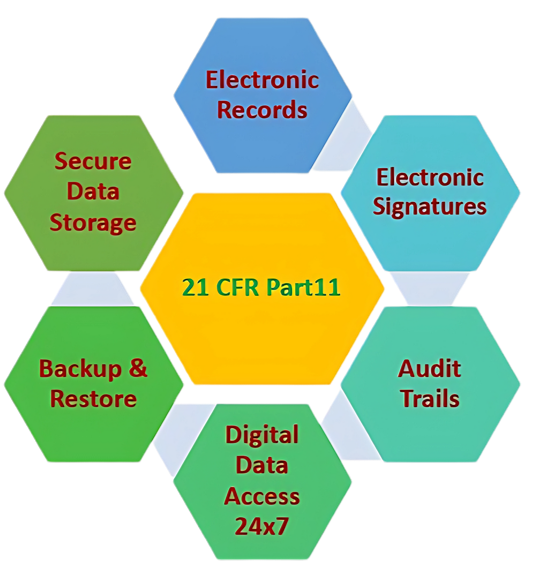

21 CFR PART 11 COMPLIANT LT-5000 FLIT

- To keep pace with the increasing use of electronic systems and technology in FDA-regulated industries, 21 CFR Part 11 was introduced, ensuring the same level of data integrity, authenticity, and reliability as paper-based systems.

- Basically, 21 CFR Part 11 is a regulation established by the U.S. Food and Drug Administration (FDA) that outlines the requirements for the use of electronic records and electronic signatures in FDA-regulated industries, including pharmaceuticals.

- Adhering to these guidelines, the introduction of Information Technology (IT) in compliance was a milestone.

- It establishes requirements for the security, integrity, and availability of electronic records and the validation of electronic systems used for GxP (Good Laboratory Practices, Good Clinical Practices, Good Manufacturing Practices) activities.

- Password-protected individual unique user account

- Password complexity

- Minimum 8 character password length

- Configurable number of wrong attempts

- User block/unblock facility

- Password validity

- Batch data is stored in a secure database format, and the Batch Report can be generated using this data.

- Report Printing: The report printing has been offered in multiple ways:

- Online printing of Alarms, Events, and Logged data through Serial Printer

- Printing of the General report through USB

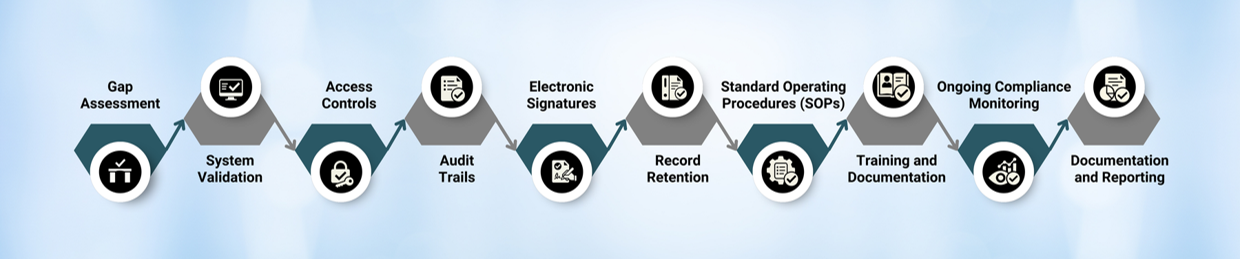

STEP FOR IMPLEMENTATION OF 21 CFR PART 11:

Services for ccit method setup:

.png)