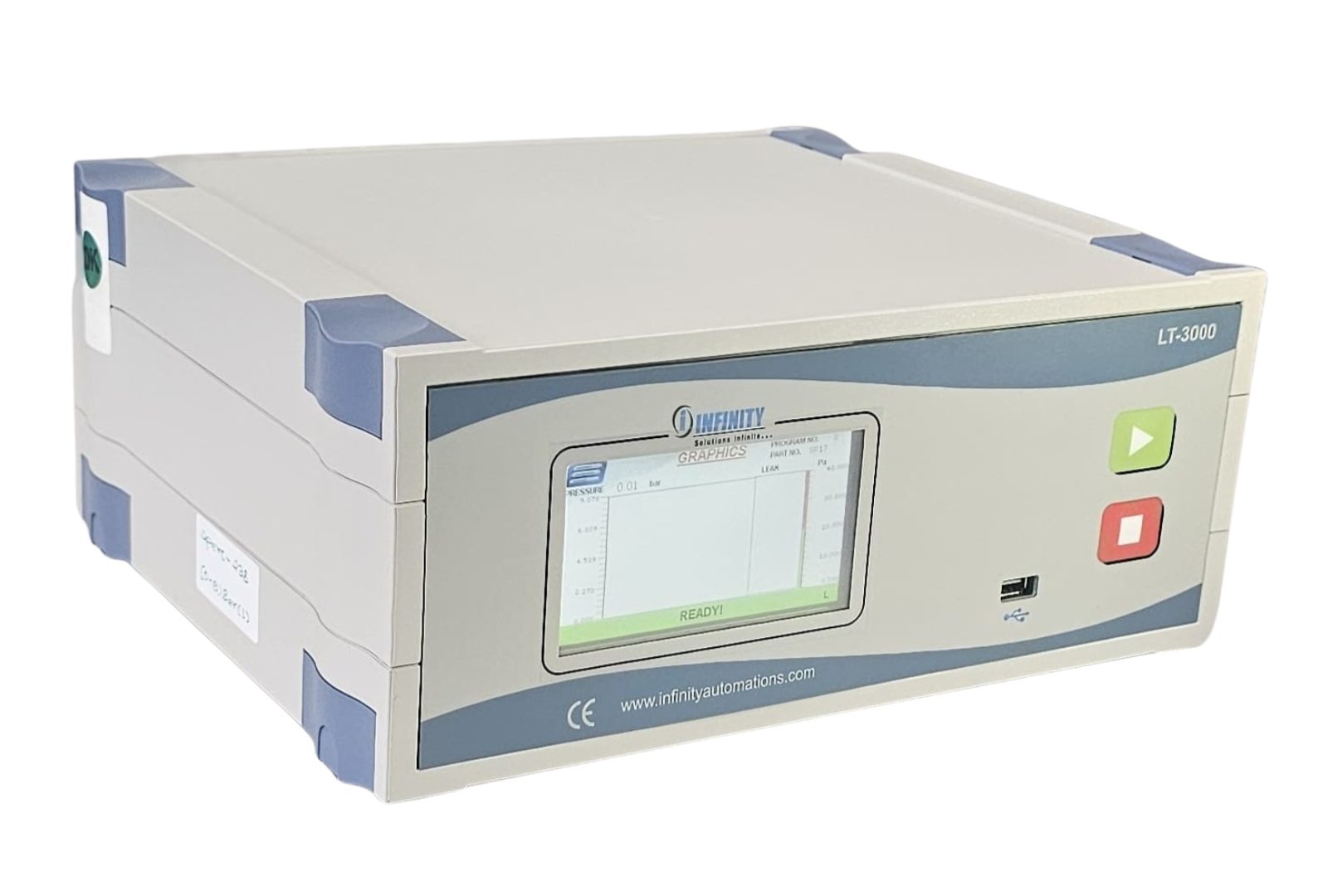

Air Leak Tester

Leak+Block+Volume

Leak Tester supports the following test methods:

- Differential Pressure / Vacuum Decay

- Pressure / Vacuum Decay

- Mass Flow Measurement

- Blockage Testing

- Volume Testing

The Infinity Leak Tester supports a wide range of testing methods, ensuring precision and adaptability across various applications. Compact, versatile, and highly configurable, the Leak Tester is readily available and can be tailored to meet specific industry or application requirements with exceptional precision.

Process:

- Suitable for all types of functional leakage detection

- Supports test durations ranging from milliseconds to several minutes

- Handles test volumes from a few milliliters to over a liter

- Designed for both individual testing and high-speed serial production environments

Compact, versatile, and highly configurable, the Leak Tester is readily available and can be tailored to meet specific industry or application requirements with exceptional precision.

Our Evolution:

Full Colour Touch Screen Graphical Display

Built-in Standard Communication Protocols.

Highly accurate up to 0.35 pascal

Direct-operating valve cuts test time by up to 1 second .

Pinch Test Detection Validates pressure ramp during fill phase.

Inbuilt storage with USB for easy data import/export.

Detects sand and foreign particles in the test part using volume analysis.

Capable of detecting blockages in casing and other components.

Data Acquisition Software:

- User-friendly Windows-based application software compatible with any operating system. Data is collected using the serial communication port of the controller.

- All the parameters of the test such as set parameters & actual parameters can be stored.

- Graphical representation of the result is possible.

- All data is available for processing using MS Access or Excel.

- Batch-wise, day-wise, and shift-wise report generation facility available for MIS purposes. Barcode printer and barcode scanner can be connected directly.

- Data can be collected from multiple controllers simultaneously.

Approvals & Achievements:

Got approval for blockage test in Mahindra and Mahindra and implemented multiple testers

Approval from Eurofins Lab Italy for CCIT with ASTM F2338-09 and USP 1207 in the pharma industry

Got approval from Electra EV for battery and battery pack leak testing

Godrej - Air spring / Wagon

Defense AFK/OFB/HEF (Mines and H2A Boxes)

Got approval from Electra EV for battery and battery pack leak testing

Got approval from TACO for EV battery and battery pack leak testing

Technical Specifications:

| Parameter | Description |

|---|---|

| Display | 4.3” TFT color touchscreen for controlling with your fingers |

| Test Pressure Range | Range -0.9 bar to 20 bars |

| Pressure Regulation | Electronic pressure regulation. Different test pressures can be set independently for each channel. |

| Communication | Modbus 485, Modbus TCP, Profinet |

| Sensing Technology | Differential pressure decay leak measurement. Usable in both pressure and vacuum conditions. |

| Program Selection | With digital input Modbus & Profinet |

| Programmable Outputs | 4 outputs for coupler / marker / cutter / etc. |

| Accessions | Leak master (on request at extra cost), external exhaust valve, quick couplers/connectors |

| Resolution | 0.1 Pascal |

| Differential Pressure Range | ± 6500 Pascal |

| Sensor Accuracy | Up to 0.035 Pascal |

| Test Pressure Units | PSI, kg/cm², bar, mbar, mmHg, cmHg, inHg, mmH₂O, kPa, etc |

| Leak Units | mL/min, L/min, mL/s, Pa/s, Pa/min, Pa, kPa, Pa·m³/s, E−3 Pa·m³/s, etc. |

| Leak Limit Range | ±999.9 Pascal |

| Number of Programs | 500 Programs |

| Timers | 999.9 seconds (resolving power: 0.1 second) |

| Power Source | Regulated 24VDC, 2A |

| USB Port | – Test data- Exporting test parameters – Test parameter backup / Restore – System backup / Restore – Upgrade |

| CPU | RISC 32-bit, 200 MHz |

| Weight | Approx. 8 to 10 kg (standard specifications) |

| Dimensions | 340 × 260 × 150 mm (W × D × H) |

Leak Test Couplers

Leak test couplers designed for secure, reliable, and quick connections during pressure or vacuum testing

- Available Sizes: 5 mm to 50 mm

- Gripping Options: Internal Diameter (ID) and External Diameter (OD) for broad compatibility

- Tool-Free Operation: Enables fast, leak-tight sealing without additional equipment

- Durable Construction: Ensures long service life and consistent performance

- Efficiency Boost: Reduces setup time and enhances overall testing productivity

- Versatile Applications: Suitable for both automated and manual leak testing setups

- Industry Use: Ideal for automotive, medical device, and industrial manufacturing sectors

Application Areas:

Data Acquisition Software:

- Ball bearing

- Bellows seal

- Brake caliper

- Brake pipes

- Catalytic exhaust pipe

- Clutch casting

- Cylinder block

- Cylinder head

- Cylinder sleeve

- Delco

- Differential gear transmission

- Engine block

- Engine rubber seals

- Exhaust manifold

- Exhaust pipe

- Fuel cap

- Fuel filter

- Fuel float

- Fuel tank

- Fuel tank cap

- Gas tank

- Gear box

- Gear box manifold

- Head light

- Head light ramp

- Heat exchanger

- Heater core

- High pressure fuel circuit

- Horn

- Hydraulic transmission

- Injection ramp

- Inlet manifold

- Inlet valve

- Inlet valve guide seal

- Jerry can

- Lip seal

- Mechanical transmission

- Oil manifold

- Oil gauge

- Oil heater

.png)