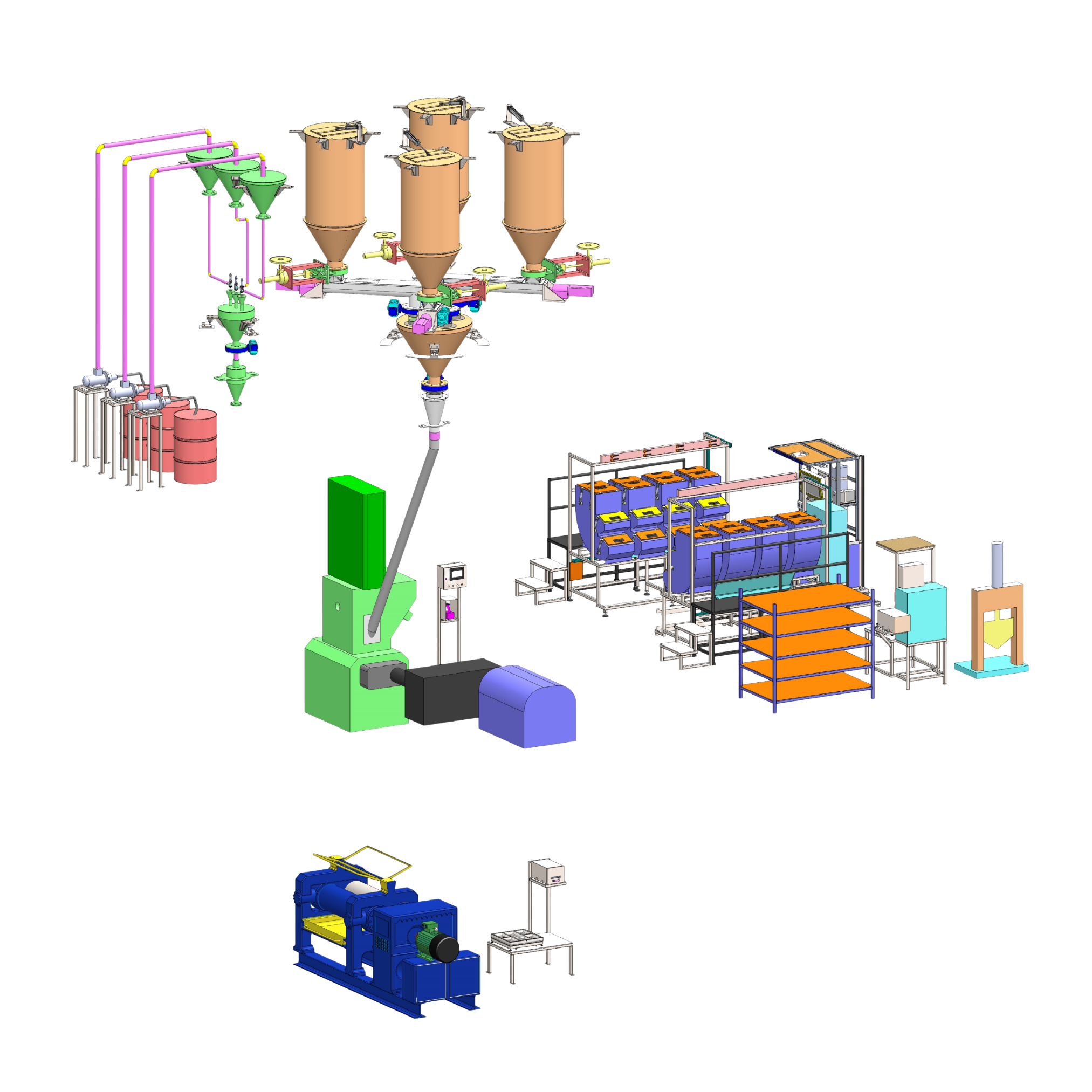

Chemical Batch Weighing

The Chemical Batch Weighing System is an advanced solution designed for precise measurement and controlled handling of chemicals during formulation.

Process

- Below 1 gm. accuracy for small chemicals

- FIFO (First In First Out) bins to retain chemical properties with time

- Dual Bin structure for area as well as cost saving

- Motorized option for central weighing for time saving and operator fatigue reduction

- User-friendly PC-based software

- Scanner-based filling mode

- Capable of storing unlimited number of formulas

- Inventories unlimited number of materials

- Tolerance control for accurate weights and batch integrity

- Lot tracking & validation features

- Multiple levels of security and password protection

- Automation of material conveying/feeding devices (dry & liquid)

Polymer Weighing

Infinity’s closed-loop system ensures precise, flexible, and integrated polymer weighing.

Process

- PLC-HMI based architecture with interlocks

- Weighing accuracy below 50 gm

- Customizable conveyors: take-off, checkweigher, and feeding

- Feeding conveyor usable standalone or with checkweigher

- Supports batch scheduling

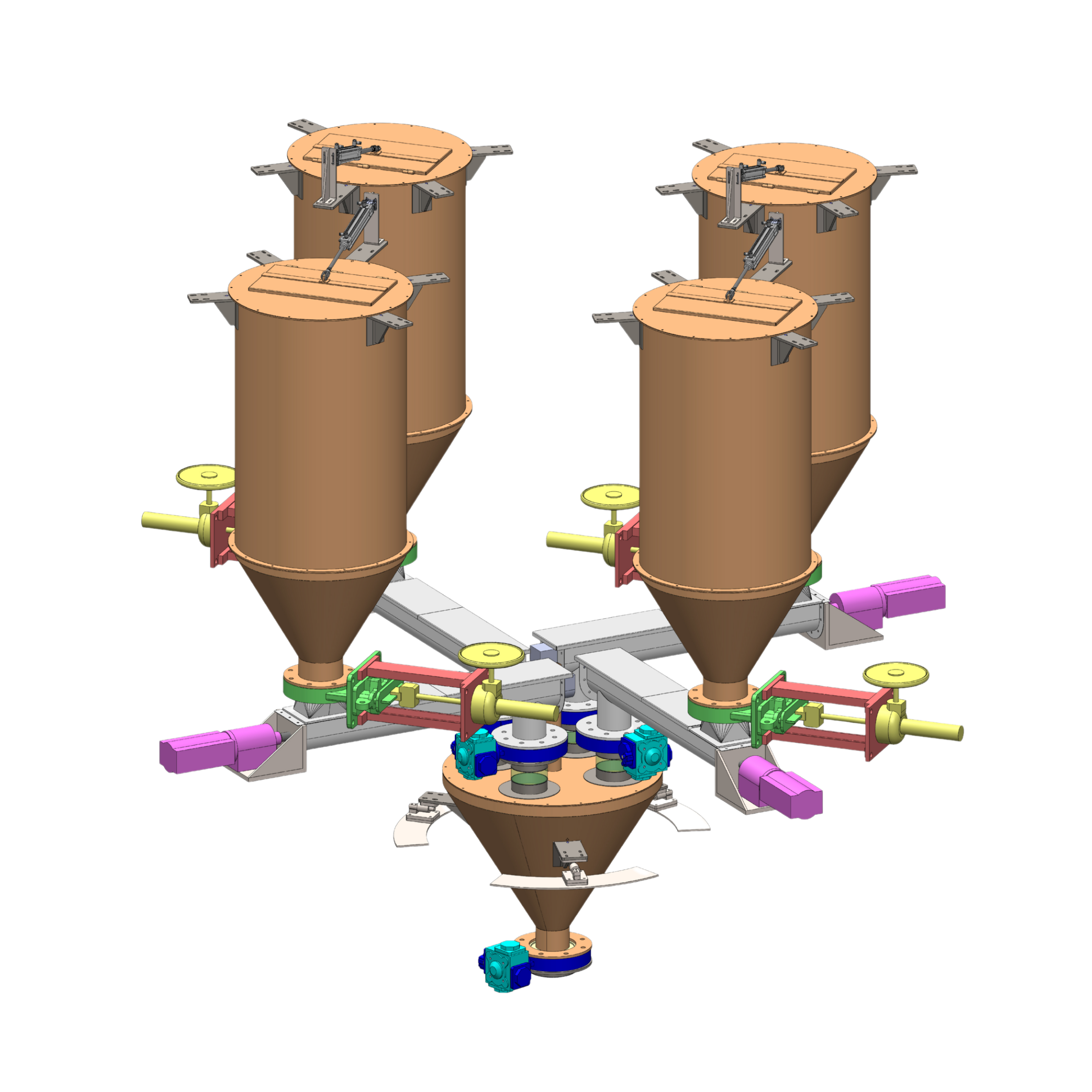

Carbon Weighing

The Carbon Batching System is designed for dust-free, sealed operation, ensuring safe and accurate raw material handling. Materials are conveyed directly to the mixer using variable-speed screw conveyors for precise dosing.

Process

- Screw-based conveying with VFD control

- Maximum accuracy up to ±10g PLC-HMI control

- SCADA integration & batch scheduling

- Supports 50kg bags and jumbo bags

- Customizable design for optimal batch time and productivity

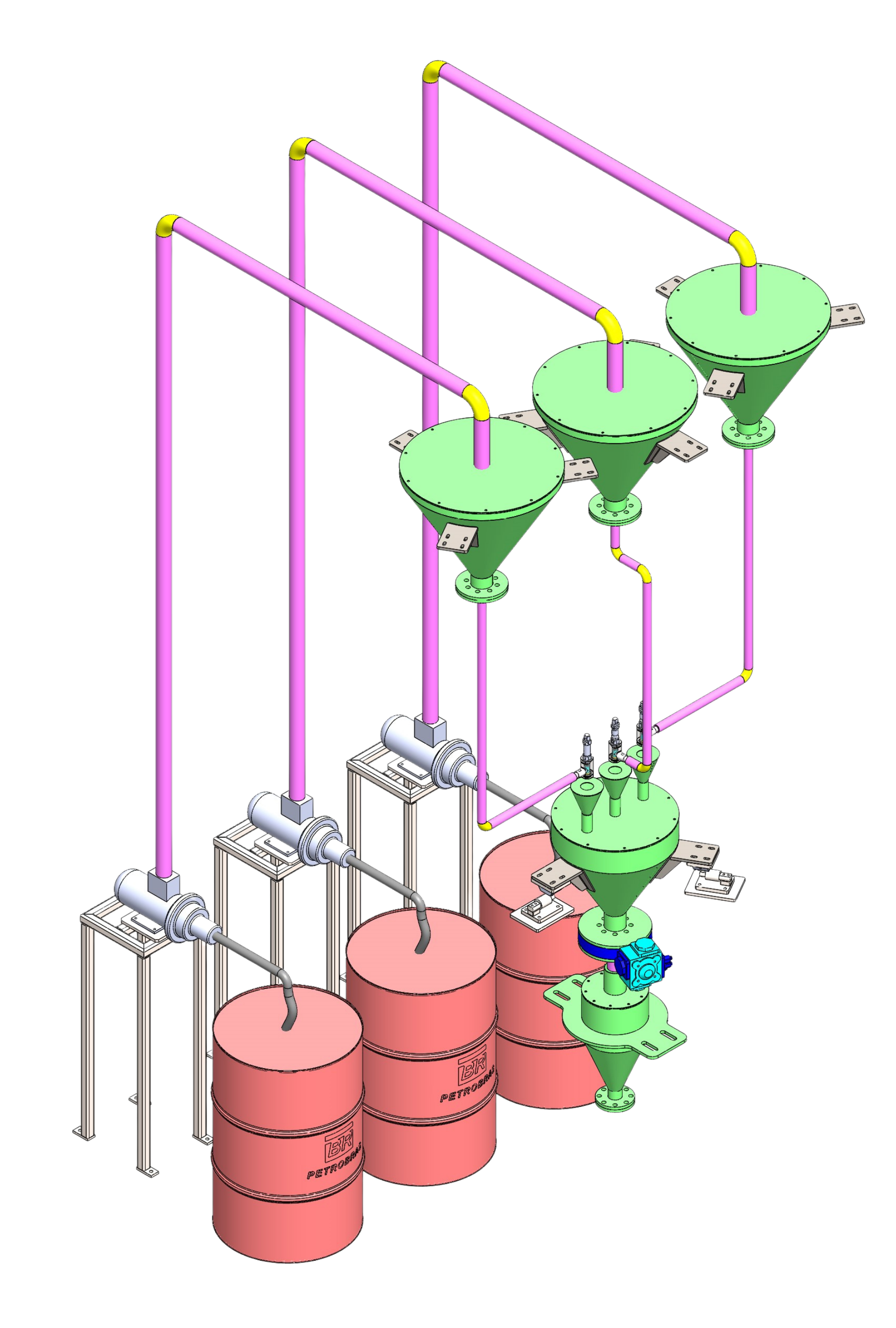

Oil Weighing

The Oil Weighing System enables precise and automated oil dispensing into mixers using a coarse-fine delivery method, ensuring clean and accurate dosing.

Process

- Auto dosing & sequencing for faster processing

- Accuracy up to ±10mg

- PLC-HMI control

- SCADA integration & batch scheduling

- Handles high/low viscosity liquids

- Heating provision for highly viscous oils

- Supports multi-oil injection with minimal cross-contamination

- Customizable for optimized batch time and productivity

Kneader/Intermix Automation

The Intermix Software manages the complete mixing process with advanced control and monitoring.

Process

- Recipe-based formulation

- Multi-stage mixing

- Centralized batch scheduling

- Chamber temperature analysis

- Automatic weighing & dispensing integration with oil weighing, polymer weighing, and carbon weighing systems

- Controls mixing time, temperature, RPM, and RAM pressure

Store management system

- Smart Inventory Control: Real-time tracking of raw materials and finished goods.

- Barcode Integration: Automated scanning and stock updates for efficient operations.

- Automated Reordering: Stock alerts and auto-replenishment when levels fall below thresholds.

- Integrated Reporting: Detailed analytics on inventory usage and trends.

- ERP Connectivity: Fully compatible with centralized data management systems.

ProdNx IT Platform

All our systems are controlled and monitored through ProdNx, a powerful IT platform designed for data recording, real-time reporting, and advanced plant management.

ProdNx Modules Include:

- ProdNx Store Management System: Real-time inventory tracking with barcode/RFID integration and automated reporting.

- ProdNx Recipe Management System: Digital recipe storage with version control and repeatable batch execution.

- ProdNx Small Chemical Management System: Intelligent weighing, dosing, and full traceability of micro-ingredients.

With ProdNx, every batch, recipe, and material movement is recorded, ensuring process transparency, regulatory compliance, and improved productivity.

News from Infinity Automation

Trade fairs & Events

Contact us

Headoffice

Would you like to contact Infinity Automation online?

Then use our online contact form!

.png)